CNJ-Antenna Embedding and Bonding Two in One Machine

Category:

Machine

Detailed introduction

Brief Introduction

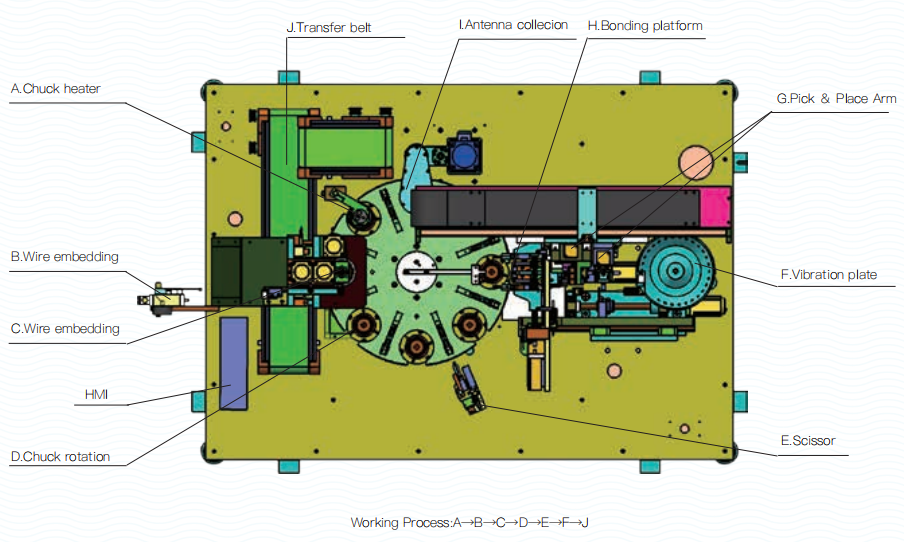

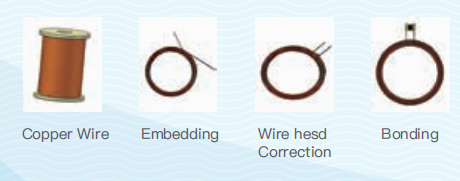

CNJLF-500 Antenna Embedding and Bonding Two in One Machine can automatic embedding antenna, at the same time, the welding chip and antenna or other metals, set antenna embedding machine and bonding machine has the advantages in a body, servo control system, using domestic ultrasonic embedding line, double pulse current inverter welding chip and antenna, welding output pulse / voltage / current / time setting digital, intuitive monitoring, energy stability of welding power adjustable, only one person operation.

Features

●With function of wire embedding, module placement and antenna bonding, which is mainly for low frequency.

●Shape and quantity of the coils can be customized as per different requirements.

●Loose modules will be transferred by vibration plate automatically.

●Module position can be checked and adjusted automatically.

●Unique design of wire fixture.

●Tool can be changed as per different requirements.

●Output of finished antenna will be transferred by belt.

Machine Process Layout Drawing

Technical Parameters

|

Item No. |

JGLF-500 |

|

Overall Dimension |

L2660 *W1500*H1900 mm |

|

Machine Weight |

Approx. 3300 kg |

|

Electricity Input |

Voltage: AC220V 50/60Hz Current: 30A |

|

Power Consumption |

6KW |

|

Compressed Air |

6.00 kg/cm² |

|

Compress Air Consumption |

1300L/min |

|

Control Technology |

Servo System+PLC Control |

|

Servo Precision |

X, Y=0.0125mm |

|

Tolerance |

±0.01mm |

|

Operator |

1 Person |

|

Pass Rate |

99.80% |

|

Applicable materials |

PVC, PETG, ABS, paper card and etc. |

|

Life time of welding tip |

About forty thousand to sixty thousand welding points |

|

Output Speed |

4000CPH |

key word:

Product manual download

Online

Message

With excellent quality and professional service, Jiaqirui products have won praise from users in various industries at home and abroad. The products are exported to more than 30 countries and regions around the world, and are highly praised by customers!